-

English

English

-

French

French

-

German

German

-

Portuguese

Portuguese

-

Spanish

Spanish

-

Russian

Russian

-

Japanese

Japanese

-

Korean

Korean

-

Arabic

Arabic

-

Irish

Irish

-

Greek

Greek

-

Turkish

Turkish

-

Italian

Italian

-

Danish

Danish

-

Romanian

Romanian

-

Indonesian

Indonesian

-

Czech

Czech

-

Afrikaans

Afrikaans

-

Swedish

Swedish

-

Polish

Polish

-

Basque

Basque

-

Catalan

Catalan

-

Esperanto

Esperanto

-

Hindi

Hindi

-

Lao

Lao

-

Albanian

Albanian

-

Amharic

Amharic

-

Armenian

Armenian

-

Azerbaijani

Azerbaijani

-

Belarusian

Belarusian

-

Bengali

Bengali

-

Bosnian

Bosnian

-

Bulgarian

Bulgarian

-

Cebuano

Cebuano

-

Chichewa

Chichewa

-

Corsican

Corsican

-

Croatian

Croatian

-

Dutch

Dutch

-

Estonian

Estonian

-

Filipino

Filipino

-

Finnish

Finnish

-

Frisian

Frisian

-

Galician

Galician

-

Georgian

Georgian

-

Gujarati

Gujarati

-

Haitian

Haitian

-

Hausa

Hausa

-

Hawaiian

Hawaiian

-

Hebrew

Hebrew

-

Hmong

Hmong

-

Hungarian

Hungarian

-

Icelandic

Icelandic

-

Igbo

Igbo

-

Javanese

Javanese

-

Kannada

Kannada

-

Kazakh

Kazakh

-

Khmer

Khmer

-

Kurdish

Kurdish

-

Kyrgyz

Kyrgyz

-

Latin

Latin

-

Latvian

Latvian

-

Lithuanian

Lithuanian

-

Lithuanian

Lithuanian

-

Macedonian

Macedonian

-

Malagasy

Malagasy

-

Malay

Malay

-

Malayalam

Malayalam

-

Maltese

Maltese

-

Maori

Maori

-

Marathi

Marathi

-

Mongolian

Mongolian

-

Burmese

Burmese

-

Nepali

Nepali

-

Norwegian

Norwegian

-

Pashto

Pashto

-

Persian

Persian

-

Punjabi

Punjabi

-

Serbian

Serbian

-

Sesotho

Sesotho

-

Sinhala

Sinhala

-

Slovak

Slovak

-

Slovenian

Slovenian

-

Somali

Somali

-

Samoan

Samoan

-

Scots Gaelic

Scots Gaelic

-

Shona

Shona

-

Sindhi

Sindhi

-

Sundanese

Sundanese

-

Swahili

Swahili

-

Tajik

Tajik

-

Tamil

Tamil

-

Telugu

Telugu

-

Thai

Thai

-

Ukrainian

Ukrainian

-

Urdu

Urdu

-

Uzbek

Uzbek

-

Vietnamese

Vietnamese

-

Welsh

Welsh

-

Xhosa

Xhosa

-

Yiddish

Yiddish

-

Yoruba

Yoruba

-

Zulu

Zulu

-

Kinyarwanda

Kinyarwanda

-

Tatar

Tatar

-

Oriya

Oriya

-

Turkmen

Turkmen

-

Uyghur

Uyghur

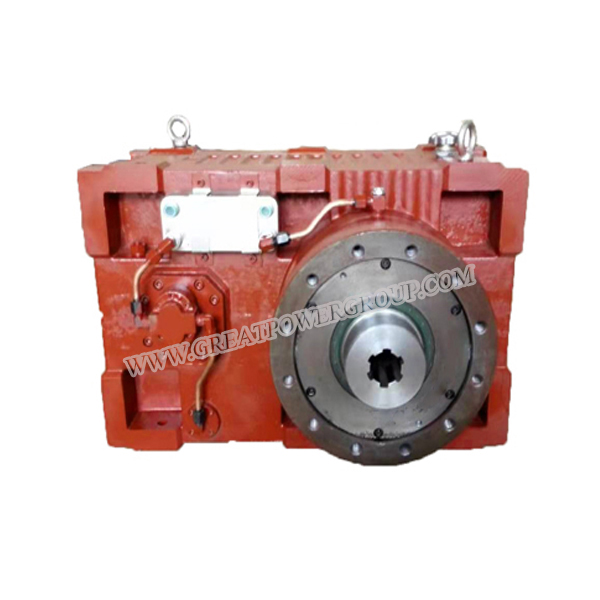

Single Screw Barrel for Injection Machine

Product Description

The screw structure and compression ratio can be precisely designed according to different products and output requirements, ensuring optimal material flow and energy efficiency. Key features include:

Adaptive Design: Screw geometry is adjustable to handle diverse materials and throughput demands.

Enhanced Stability: Advanced barrel heating and cooling systems maintain uniform melt temperature, reducing material degradation.

Durability: Constructed with high-grade alloys to withstand high-pressure extrusion environments, extending operational lifespan.

Technical Specification

Material:38CrMoAlA, 42CrMo(JIS SCM440), SKD11,61

Diameter:Φ15mm-350mm

Nitride Case Depth:0.5mm-0.8mm

Nitride Hardness:1000-1100HV

Nitride Brittleness:≤Grade One

Surface Roughness:Ra0.4um

Screw Straightness:0.015mm

Alloy Hardness:HRC68-72

The ratio of length to diameter: L/D=12-45

Types of Screws

Multiple configurations available to match processing needs:

Gradual Type: Ideal for gentle material compression in sensitive polymers.

Mutant/Wave Type: Enhances mixing for composite materials.

Barrier/Double Screen Type: Prevents backflow in high-viscosity applications.

Shunt/Separation Type: Optimizes multi-material extrusion.

Exhaust/Pin Type: Removes volatiles during recycling processes.

Mixed/Double-Head/Multi-Head Type: Boosts output for large-scale production lines.

Application

It is widely used to cable , sheet , pipe , profile,etc.